Design and Implementation of Smart Forklift for Automatic Guided Vehicle Using Raspberry Pi 4

DOI:

https://doi.org/10.18196/jrc.26130Keywords:

AGV, Forklift Mechanism, SPR, Raspberry PiAbstract

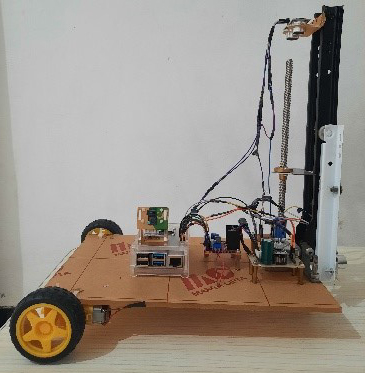

Automatic Guided Vehicle (AGV) pallet truck is widely used in the industry. This kind of AGV is such a combination of the ordinary AGV used forklift mechanism. The forklift mechanism is employed for lifted up or carrying things from one place to another place. As the technology has been developed along with the industry revolution 4.0, therefore, the activity could be done automatically by using a robot-like AGV pallet truck. Basically, the working principle of the AGV pallet truck is similar to the ordinary forklift whereas the AGV pallet truck is automatically operated. DC motor is applied as the driving force for the uplifting and down lifting process in the forklift mechanism of the AGV pallet truck. DC motor is chosen because it has large torque which is advantageous for lifting loads. Unfortunately, DC motor also owns some disadvantages such as high maintenance fees and less precision. This study proposes a smart forklift mechanism for AGV pallet trucks that utilizes a stepper motor and ultrasonic distance sensor. This smart forklift mechanism is equipped with raspberry pi model B as the main microcontroller and combined with an ultrasonic distance sensor. The result of the ultrasonic distance sensor has an error approaching zero percent so the precision of the height can be fully controlled. Step / Revolution (SPR) method makes the stepper motor can move smoothly like micro-step and also the number of rotations can be controlled as we want.

References

S. I. Tay, T. C. Lee, N. Z. A. Hamid, and A. N. A. Ahmad, “An overview of industry 4.0: Definition, components, and government initiatives,” J. Adv. Res. Dyn. Control Syst., vol. 10, no. 14, pp. 1379–1387, 2018.

A. Rojko, “Industry 4.0 concept: Background and overview,” Int. J. Interact. Mob. Technol., vol. 11, no. 5, pp. 77–90, 2017, doi: 10.3991/ijim.v11i5.7072.

D. Susilo, “Industry 4.0: Is Indonesia Ready?,” Manag. Anal. J., vol. 9, no. 3, pp. 262–270, 2020, doi: 10.15294/maj.v9i3.39695.

A. Hidayatno, A. R. Destyanto, and C. A. Hulu, “Industry 4.0 technology implementation impact to industrial sustainable energy in Indonesia: A model conceptualization,” Energy Procedia, vol. 156, no. January, pp. 227–233, 2019, doi: 10.1016/j.egypro.2018.11.133.

B. Ślusarczyk, “Industry 4.0 – Are we ready?,” Polish J. Manag. Stud., vol. 17, no. 1, pp. 232–248, 2018, doi: 10.17512/pjms.2018.17.1.19.

J. Nagy, J. Oláh, E. Erdei, D. Máté, and J. Popp, “The role and impact of industry 4.0 and the internet of things on the business strategy of the value chain-the case of hungary,” Sustain., vol. 10, no. 10, 2018, doi: 10.3390/su10103491.

V. Sima, I. G. Gheorghe, J. Subić, and D. Nancu, “Influences of the industry 4.0 revolution on the human capital development and consumer behavior: A systematic review,” Sustain., vol. 12, no. 10, 2020, doi: 10.3390/SU12104035.

J. P. Spicer, N. Huang, G. Vanderheyden, and J. O’Dell, “AUTOMATED GUIDED VEHICLE SYSTEM,” IRJET, pp. 4038–4043, 2018.

A. J. Moshayedi, L. Jinsong, and L. Liao, “AGV (automated guided vehicle) robot: Mission and obstacles in design and performance,” J. Simul. Anal. Nov. Technol. Mech. Eng., vol. 12, no. 4, pp. 5–18, 2019.

N. Correia, L. Teixeira, and A. L. Ramos, “Implementing an AGV system to transport finished goods to the warehouse,” Adv. Sci. Technol. Eng. Syst., vol. 5, no. 2, pp. 241–247, 2020, doi: 10.25046/aj050231.

E. A. Oyekanlu et al., “A Review of Recent Advances in Automated Guided Vehicle Technologies: Integration Challenges and Research Areas for 5G-Based Smart Manufacturing Applications,” IEEE Access, vol. 8, pp. 202312–202353, 2020, doi: 10.1109/access.2020.3035729.

M. S. S. Kaliappan, J. Lokesh, P. Mahaneesh, “Mechanical Design and Analysis of AGV for Cost Reduction of Material Handling in Automobile Industries,” Int. Res. J. Automot. Technol., vol. 1, no. 1, pp. 1–7, 2018.

A. M. T. I. Al-Naib, “Stepper Motor,” ResearchGate, 2019.

C. Dey, A. Mukhopadhyay, and S. Sarkar, “Automated Guided Vehicle Based Material Handling System : A Survey,” vol. 8, no. 9, pp. 4–9, 2020.

C. Llopis-Albert, F. Rubio, and F. Valero, “Designing Efficient Material Handling Systems Via Automated Guided Vehicles (AGVs),” Multidiscip. J. Educ. Soc. Technol. Sci., vol. 5, no. 2, p. 97, 2018, doi: 10.4995/muse.2018.10722.

M. Abdellatif, M. Shoeir, O. Talaat, M. Gabalah, M. Elbably, and S. Saleh, “Design of an autonomous forklift using kinect,” MATEC Web Conf., vol. 153, pp. 1–5, 2018, doi: 10.1051/matecconf/201815304005.

A. Suryowinoto and M. Wijayanto, “The prototype of A Forklift Robot Based on AGV System and Android Wireless Controlled for Stacked Shelves,” Int. J. Artif. Intell. Robot., vol. 2, no. 1, p. 1, 2020, doi: 10.25139/ijair.v2i1.2621.

O. Mahmood Altaee, A. Ibraheem Alnaib, and N. Abed AlBary Aljawady, “Design and Realization of a Stepper Motor Driver with PLC,” Al-Kitab J. Pure Sci., vol. 2, no. 1, 2018, doi: 10.32441/kjps.v2i1.137.

S. Ricci and V. Meacci, “Simple torque control method for hybrid stepper motors implemented in FPGA,” Electron., vol. 7, no. 10, 2018, doi: 10.3390/electronics7100242.

S. K. Das and M. K. Pasan, “Design and Methodology of Automated Guided Vehicle-A Review,” ResearchGate, no. April, 2016.

S. J. Johnston and S. J. Cox, “The raspberry Pi: A technology disrupter, and the enabler of dreams,” Electron., vol. 6, no. 3, 2017, doi: 10.3390/electronics6030051.

T. N. Trong, “The control structure for dc motor based on the flatness control,” Int. J. Power Electron. Drive Syst., vol. 8, no. 4, pp. 1814–1821, 2017, doi: 10.11591/ijpeds.v8i4.pp1814-1821.

A. A. Hassan, N. K. Al-Shamaa, and K. K. Abdalla, “Comparative Study for DC Motor Speed Control Using PID Controller,” Int. J. Eng. Technol., vol. 9, no. 6, pp. 4181–4192, 2017, doi: 10.21817/ijet/2017/v9i6/170906069.

C. Wang and D. Cao, “New sensorless speed control of a hybrid stepper motor based on fuzzy sliding mode observer,” Energies, vol. 13, no. 18, 2020, doi: 10.3390/en13184939.

L. N. Roshanna and N. R. Konduru, “IoT Based Stepper Motor Position Control for Industrial Automation,” Am. J. Sci. Eng. Technol., vol. 2, no. 4, pp. 106–111, 2017, doi: 10.11648/j.ajset.20170204.12.

and M. A. E.-H. H.M.N. Fiyad, H.M.B. Metwally, “Application of Micro-Controllers for Stepper Motors Position and Speed Control: A Review,” Int. J. Sci. Eng. Res., vol. Volume 10, no. 5, 2019.

M. Y. Stoychitch, “Generate stepper motor linear speed profile in real time,” IOP Conf. Ser. Mater. Sci. Eng., vol. 294, no. 1, 2018, doi: 10.1088/1757-899X/294/1/012055.

R. Borkar and T. Aga, “Simulation and Development of Stepper Motor for Badminton Playing Robot,” Www.Ijmer.Com, vol. 5, pp. 57–62, 2015.

E. Yılmazlar, V. Erdemir, H. Kuşçu, and A. Güllü, “Design Of Stepper Motor Control Interface With Embedded Systems,” Int. J. Eng. Res. Dev., vol. 14, no. 6, pp. 17–22, 2018.

R. Subasri and A. Aarthy, “Speed estimation in DC motor using raspberry Pi processor,” Int. J. Sci. Technol. Res., vol. 9, no. 3, pp. 3213–3218, 2020.

Downloads

Published

How to Cite

Issue

Section

License

Authors who publish with this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).

This journal is based on the work at https://journal.umy.ac.id/index.php/jrc under license from Creative Commons Attribution-ShareAlike 4.0 International License. You are free to:

- Share – copy and redistribute the material in any medium or format.

- Adapt – remix, transform, and build upon the material for any purpose, even comercially.

The licensor cannot revoke these freedoms as long as you follow the license terms, which include the following:

- Attribution. You must give appropriate credit, provide a link to the license, and indicate if changes were made. You may do so in any reasonable manner, but not in any way that suggests the licensor endorses you or your use.

- ShareAlike. If you remix, transform, or build upon the material, you must distribute your contributions under the same license as the original.

- No additional restrictions. You may not apply legal terms or technological measures that legally restrict others from doing anything the license permits.

• Creative Commons Attribution-ShareAlike (CC BY-SA)

JRC is licensed under an International License